A Project for sustainable recycling in the automotive

In a project called EKODA that will last from November 1, 2022, until the end of 2025, several Centers of the Frankfurter Institute (Germany) and various industrial companies will address the possibilities of creating the foundations for a sustainable circular economy of products.

Automotive especially focused on vehicles equipped with new technologies both propulsion and automation that are built in the future.

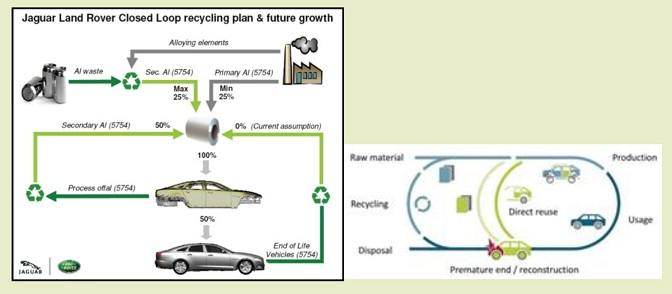

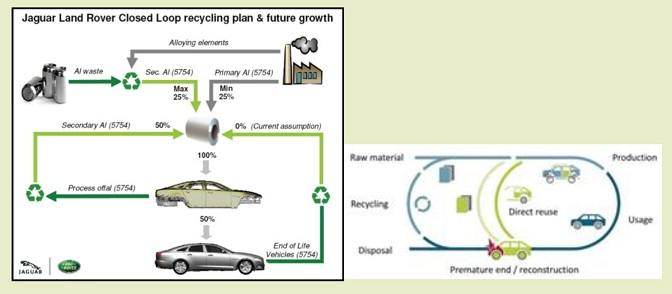

It has been organizations defined as recycling those that took charge of disabled vehicles, both coming from premature ends (accidents) and those discarded by users.

In its plants, a series of operations are carried out using only labor and energy for the structural parts that repair shops acquire and mechanical elements without any type of analysis or guarantee follow the same path.

When there is nothing usable left, they are crushed or packaged as scrap for smelting furnaces.

The greatest advance has been the requirement to previously remove fuel, grease, and other dangerous or polluting fluids.

The EKODA project proposes, first of all, to examine each component of the vehicle with all characteristics through a complex test procedure.

An evaluation system will then generate recommendations on how to reuse your components. This AI-based strategy will optimize the lifespan of individual parts, enabling a sustainable circular economy to be established in the mobility sector.

Used batteries, axles, and gears could even have other applications outside of the automotive industry.

Batteries will be the most important item to consider. A camera acting on a battery will record the type, model, series, power, etc., and compare this information with a database.

Next, the current charge level, functionality of its control electronics, and status of each of the cells would be discovered and carried out further.

The assessment developed will use this data to create a detailed profile of the state of the battery to offer recommendations for reuse.

An intact three or four-year-old battery, for example, could be transferred to a used car of the same type. If the energy storage system is older, it might be possible to use it in a smaller farm machine.

Even if the battery has several defective cells, it could serve as electricity storage in home photovoltaic systems.

It would act similarly to body parts and mechanics. Even loose parts like axles or gears can be valuable as raw materials for other constructions.

Ecological criteria will have the same importance as technological and economic factors, such as CO2 emissions and energy consumed during reuse.

Related Post